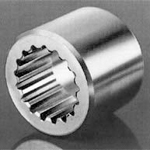

Spur gear

Machining details

Gear milling

- straight and oblique

- module 0.5 to module 8

- to 630 mm diameter

Skiving

Gear tooth forming

- to module 6

- external to 500 diameter

- internal to 440 diameter

Flank grinding

- to module 6

- straight and oblique

- bevelled and crowned

- to 330 diameter

Flank honing

- to module 4 and 200 diameter

Documentation on request

Worm

Machining details

Gearwheel

Gear tooth milling and flank grinding

- to module 8

Worm wheel

Gear tooth milling

- to module 8 and 630 diameter

Toothed belt wheel

Machining details

Gear tooth milling

- to 630 diameter

Kettenräder

Machining details

Gear tooth milling

- to 630 diameter

Gear tooth forming

- to 500 diameter

Geared shaft and splined shaft

Machining details

Gear tooth milling

- to 250 diameter and 2000 length

Gear rack

Machining details

Gear tooth milling

- to module 8 and 1700 length

Special profile

Machining details

Gear tooth milling and forming on request

Geared hub, splined hub and groove

Machining details

Gear tooth broaching and forming

DIN 5463, DIN 5480, DIN 5481, DIN 5482, ANSI, SAE, BS, NF

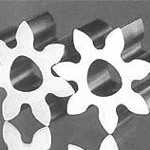

Oil pump gear

Oil pump wheels are used in racing engines.

Machining details

flank ground and flank honed

Beveloid wheel /bevelled helical gear

These components are required when axes are inclined in space.

Machining details

bevel and oblique toothed

Planetary gear sets

Planetary gear sets are used wherever loads are moved (e.g. in wheelchairs, stair climbers, crane winches).

Coupling part

Machining details

crown toothed

Non-round gear

Out of round gears are used when asymmetric movements are required.

Machining details

Verzahnungsstoßen

Gearwheel

Machining details

bevelled and crown toothed

This post is also available in: German